3. Consumer electronics: Rapid prototyping allows electronics corporations to develop and test new product concepts rapidly. This helps them evaluate consumer experience, ergonomics, functionality, and aesthetics before launching the ultimate product out there. 4. Healthcare trade: Rapid prototyping is extensively used in medical gadget development, enabling the creation of prototypes for surgical tools, prosthetics, implants, and customised anatomical fashions for preoperative planning. It facilitates faster innovation in healthcare technology and improves patient outcomes. In conclusion, rapid prototyping has revolutionized the R&D course of by providing researchers with a powerful software to quickly transform ideas into tangible prototypes. Its significance lies in reducing time-to-market, bettering price-effectiveness, enhancing innovation potential, and enabling early identification of design flaws or constraints. By employing methodologies such as 3D printing, CNC machining, and laser chopping, rapid prototyping offers immense worth throughout varied industries like automotive, aerospace, consumer electronics, healthcare, and more. Rapid prototyping has emerged as a vital tool in the field of research and growth (R&D), enabling researchers to shortly validate and refine their concepts before committing significant sources.

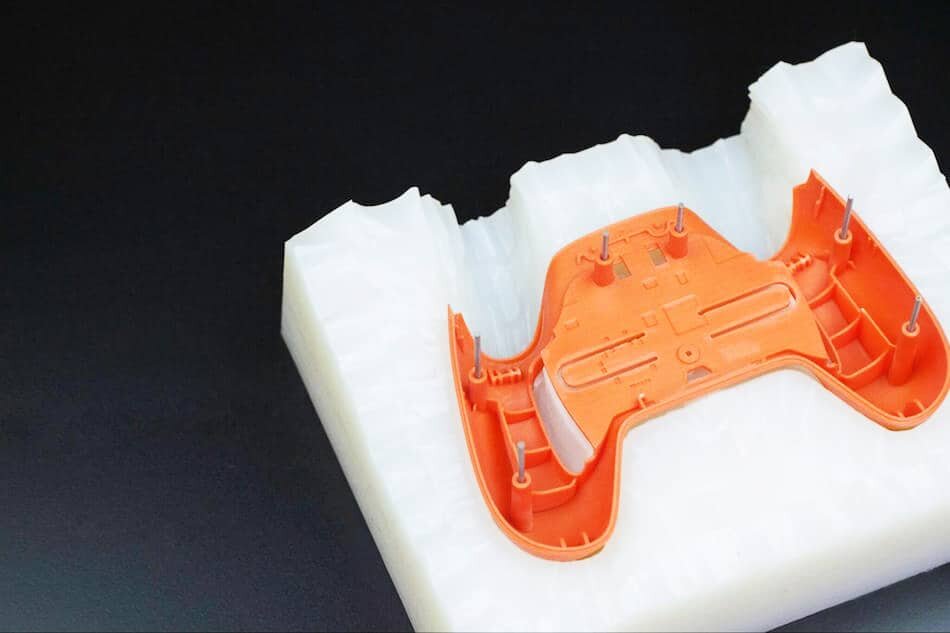

Rapid prototyping and engineering is a process that allows engineers and designers to shortly create a physical prototype of a product. It entails the usage of laptop-aided design (CAD) software program and 3D printing technology to supply a physical model of a component or product. The aim of rapid prototyping is to allow for quick and easy testing and evaluation of product designs earlier than committing to mass production. By making a bodily prototype, designers can take a look at the performance, match, and form of a product, and make vital modifications earlier than investing in expensive tooling and manufacturing. Rapid prototyping has grow to be an essential device for engineers and designers in a wide range of industries, together with aerospace, automotive, medical, and shopper merchandise. We excel in rapid prototyping and engineering and a number one firm offering selective laser sintering technology to the customers for creating rapid prototypes. For additive manufacturing of 3D elements with complicated shapes, you'll be able to belief the companies.

Rapid prototyping and engineering is a process that allows engineers and designers to shortly create a physical prototype of a product. It entails the usage of laptop-aided design (CAD) software program and 3D printing technology to supply a physical model of a component or product. The aim of rapid prototyping is to allow for quick and easy testing and evaluation of product designs earlier than committing to mass production. By making a bodily prototype, designers can take a look at the performance, match, and form of a product, and make vital modifications earlier than investing in expensive tooling and manufacturing. Rapid prototyping has grow to be an essential device for engineers and designers in a wide range of industries, together with aerospace, automotive, medical, and shopper merchandise. We excel in rapid prototyping and engineering and a number one firm offering selective laser sintering technology to the customers for creating rapid prototypes. For additive manufacturing of 3D elements with complicated shapes, you'll be able to belief the companies.

All of the rapid prototyping applied sciences in present use have many issues in frequent. All make use of additive processes. Rapid prototyping makes use of additive development because the means of making strong prototype objects which has the distinct advantage of making virtually any shape or type that even the very best machining and tooling strategies is probably not ready to attain. In the course of the ensuing improvement, virtual prototyping goes through quite a lot of phases that ultimately turns designs into fully testable three dimensional fashions. All the rapid prototyping machines being used slowly type the three dimensional fashions by placing together skinny, two-dimensional layers one at a time. The three dimensional manifestation of the digital design is formed from the bottom up. Models are formed on an elevator-like platform from digital CAD designs. The platform is lowered a layer-peak at a time as soon as a layer is completed. The thinner the layer, the smoother the end will probably be on the accomplished prototype mannequin. Once the mannequin is completely formed, it could also be sanded, plated or painted, relying on material used. Rapid prototyping technologies can either be a "dry" or a "wet" process. Most machines create prototype models by solidifying some type of free powder, liquid, or semi-liquid materials. A machine could also be ready to cut by means of adhesive-coated sheets of prototype fabrication materials. The dry powdered supplies can either be some type of polymer, powdered steel, or wax. Some machines may even be ready to use starch as the constructing materials for forming the prototype mannequin. A number of the powders used might also require a binder. The liquid materials mainly used are often photosensitive polymers that solidify when exposed to either a laser or ultraviolet (UV) light. If you have any thoughts with regards to where by and how to use 3d printing blogs, you can speak to us at our own internet site. Wet rapid prototype Shenzhen strategies usually require a curing phase.

Rapid prototyping is a part of Rapid Application Development however is often used in the agile framework, the place it's utilized in almost every stage of improvement. Agile methodologies like Kanban, for instance, use rapid prototyping to help attain particular target targets or releases. The Scrum methodology uses rapid prototyping to translate the scope of a mission into last sprints. Even the hybrid Scrumban method can utilize speedy app design to focus on longer-time period targets and the ultimate launch date. Rapid prototyping of intricate interactive fashions helps massive-scale initiatives the place the prototype needs to be broken down into particular purposeful components. Development teams can then get a 360-degree view of the product as an entire and the particular options they are chargeable for creating. In iterative app design, rapid prototyping is used to create iterative prototypes to match sprints’ frequency. They often bear minor adjustments that ultimately go into the ultimate product.

Rapid prototyping is a part of Rapid Application Development however is often used in the agile framework, the place it's utilized in almost every stage of improvement. Agile methodologies like Kanban, for instance, use rapid prototyping to help attain particular target targets or releases. The Scrum methodology uses rapid prototyping to translate the scope of a mission into last sprints. Even the hybrid Scrumban method can utilize speedy app design to focus on longer-time period targets and the ultimate launch date. Rapid prototyping of intricate interactive fashions helps massive-scale initiatives the place the prototype needs to be broken down into particular purposeful components. Development teams can then get a 360-degree view of the product as an entire and the particular options they are chargeable for creating. In iterative app design, rapid prototyping is used to create iterative prototypes to match sprints’ frequency. They often bear minor adjustments that ultimately go into the ultimate product.