What are the Forms of PCB Assembly Processes? Printed circuit boards are used in practically anything electronic, together with toys for kids, cars, and equipment for industrial manufacture. PCBs are essential to numerous functions and are made from fibreglass, epoxy, metallic parts, and a inexperienced solder mask. The elements are arranged on it to allow the PCB to perform as supposed. The PCB’s functionality is what matters most. Even when a tiny SMT resistor shouldn't be put in accurately or somewhat track is removed from the PCB maker, the PCB may still not perform. Therefore, the parts must be put collectively appropriately. Printed circuit boards, generally known as rigid-flex boards, combine stiff and flexible board technology. Depending on the application’s structure, most inflexible-flex boards are built from many layers of versatile circuit substrates outwardly or internally related to one or more rigid boards. The versatile substrates are frequently moulded into the flexed curve during manufacturing or installation since they're supposed to be flexible at all times.

You can not assemble various parts using SMT know-how, although it has replaced other mounting methods in PCB fabrication. Then, the same board have to be used for printed circuit board THT and SMT assembly. A blended meeting makes use of varied methods however doesn’t require solder paste in the manufacturing course of. Many elements need to get welded with a surface mount association on the board, except just a few speciality components that are not accessible by means of the SMT course of and have to be constructed utilizing blended PCB. Electronic circuits are constructed utilising the via-hole assembly approach, by which leads are employed to place the parts. It describes the assembly procedure, wherein the leads are inserted into the pre-drilled holes before the elements are joined to the board using either wave soldering or manual soldering. PCB design has traditionally used multi-layer, double-layer, and single-sided boards. Through-gap meeting is difficult to adapt to the wants of contemporary electronics. Today, SMT know-how has largely taken the place of through-hole meeting within the manufacturing of PCBs.

You can not assemble various parts using SMT know-how, although it has replaced other mounting methods in PCB fabrication. Then, the same board have to be used for printed circuit board THT and SMT assembly. A blended meeting makes use of varied methods however doesn’t require solder paste in the manufacturing course of. Many elements need to get welded with a surface mount association on the board, except just a few speciality components that are not accessible by means of the SMT course of and have to be constructed utilizing blended PCB. Electronic circuits are constructed utilising the via-hole assembly approach, by which leads are employed to place the parts. It describes the assembly procedure, wherein the leads are inserted into the pre-drilled holes before the elements are joined to the board using either wave soldering or manual soldering. PCB design has traditionally used multi-layer, double-layer, and single-sided boards. Through-gap meeting is difficult to adapt to the wants of contemporary electronics. Today, SMT know-how has largely taken the place of through-hole meeting within the manufacturing of PCBs.

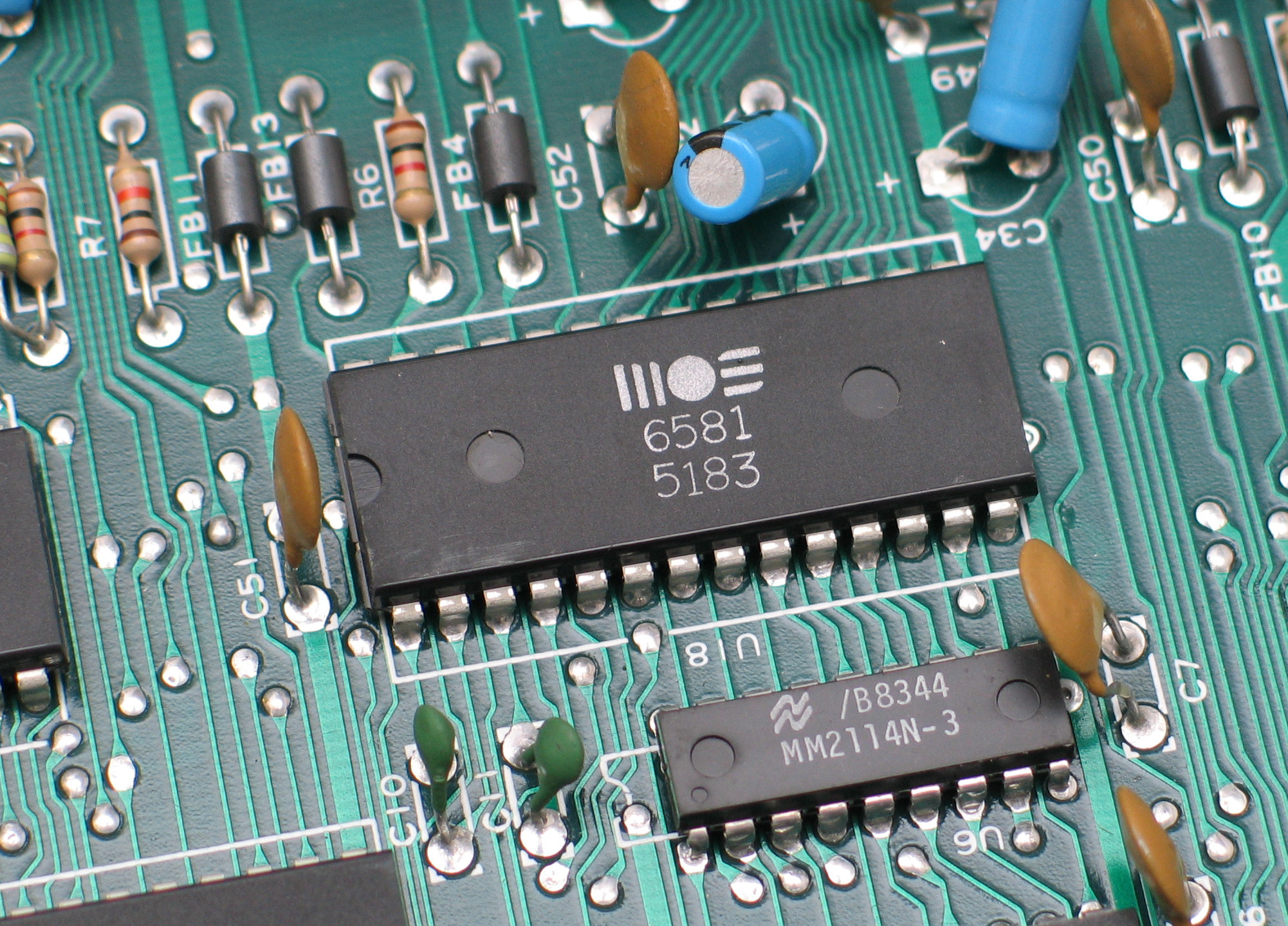

However, some functions, resembling those utilising electrolytic capacitors, connections, and substantial transformers, still call for via-gap installation. Surface-mount devices referred to as ball grid arrays (BGA), also known as chip carriers, PCB buying guide are used for packaging built-in circuits. Microprocessors are put in permanently by way of BGA packaging. A BGA can accommodate extra connector pins than a twin in-line or flat design. Instead of merely utilizing the edge, the device’s entire backside floor can be used. A perimeter-solely kind often has shorter traces than another, which improves efficiency at high speeds. These traces join the package’s results in the balls or wire and join the bundle and the die. Surface Mount Technology, or SMT, is the official name. SMT is a technique for attaching components or parts to circuit boards. SMT’s superior outcomes and enhanced effectiveness have compelled the replacement of traditional PCB assembly strategies. In the past, through-gap assembly was largely used by PCB manufacturers to add elements. However, welding expertise has replaced the previous assembling approach in SMT. All digital businesses, together with those in computer systems, phones, smartphones, dwelling appliances, etc., make use of PCBs made using the SMT meeting method. Printing solder paste, mounting elements, reflow soldering, and finishing up AOI or AXI are the basic procedures in SMT assembly. Most PCBs that deliver high voltage or present have a separate aircraft for ground connections. The highest layer’s digital components are "Vias" connecting to the inner GND aircraft or indicators layer. You need to use any of the above processes, however ensure to have the suitable tools.

The trial software program is free. Start using the absolutely licensed software for as little as $500. As per Mark Twain's well-known quote, "The man who doesn't read good books has no benefit over the man who cannot learn them.". Much like the style in which perusing quality literature provides an edge, using Unisoft's ProntoVIEW-MARKUP and different software program from our suite will present a significant benefit. With 35 years of growth, our software ensures improved effectivity and accuracy, enabling you to supply higher high quality assembled boards in less time. ProntoVIEW-MARKUP is a software software utilized by electronic manufacturers in PCB assembly (PCBA) for detailed inspection of Pc board assemblies and creating crucial paperwork all through the PCBA course of. This software gives enhanced effectivity, communication, and diminished errors throughout the manufacturing ground. Featuring more than a hundred options, ProntoVIEW-MARKUP benefits every division inside PCB assembly (PCBA) manufacturers, including administration, meeting, inspection, design, testing, troubleshooting technicians, and other personnel.

This software creates meeting instructions with distinctive colors for each part quantity and step in the meeting process and generates corresponding kitting labels. Should you loved this article and you would love to receive more information regarding PCB buying guide assure visit our website. It additionally assists in locating any element, pcb assembly pin, or part quantity, finding shorts between traces, netlists, paperless hyperlinked schematic links to the assembly, including annotation notes and graphics, and gives quick Pc Board first article inspection and normal inspection. Additionally, ProntoVIEW-MARKUP generates studies that include gadget and bundle type counts along with value estimates. You possibly can distribute the Unisoft included Pc Board viewer software to your production flooring, vendors, and clients with a current license to aid assembly, 1st article inspection, normal inspection, repair/rework, technician debug, for better communication, and extra. Furthermore, if obligatory, ProntoVIEW-MARKUP will be managed remotely out of your software or gear by way of the supplied exterior API programming interface. When you've got a question use the email that follows or name us. Online meetings are usually the quickest technique to be taught about the Unisoft software. We are able to go surfing nearly anytime to reply questions and process one among your Pc Board tasks or use our information information to indicate you the software.