Schroeder Industries’ TNK collection is constructed for exceptional durability in a wide range of working situations. The TNK Sequence offer complete hydraulic reservoir options with pre-installed equipment, gauges, and air breathers. These reservoirs are engineered to last and enhance your equipment’s effectivity. With 4, 7, 12, 18, and 25 gallon options with potential for custom solutions, there’s a TNK for each system! Hydraulic tanks enable any contaminants to settle at the underside of the tank and can also feature filters to scale back contamination even more effectively. Launch air: A hydraulic reservoir permits air to separate from the hydraulic fluid and escape by the breather at the top of the tank. Releasing air from the system protects it since air within the system may cause severe damage. Hydraulic tanks don’t have a one-measurement-suits-all resolution. At Superior Manufacturing Company, we create custom hydraulic tanks for OEMs and other heavy-responsibility manufacturers. With over 75 years in business, now we have the experience to make excessive-quality metallic hydraulic tanks that meet your specs and gear necessities. We handle every aspect of manufacturing, from fabrication and painting to meeting and high quality control.

Complete system checks: Depending on the conditions of your system, you and your group should perform complete techniques checks month-to-month, quarterly or annually. Duties should embody working a comprehensive report on the system, cleansing devices, draining the system and replacing damaged elements. When completing system maintenance, it is essential to comply with basic safety procedures. Faulty or broken parts could cause leaks, bursts and projectiles that can severely injure personnel.

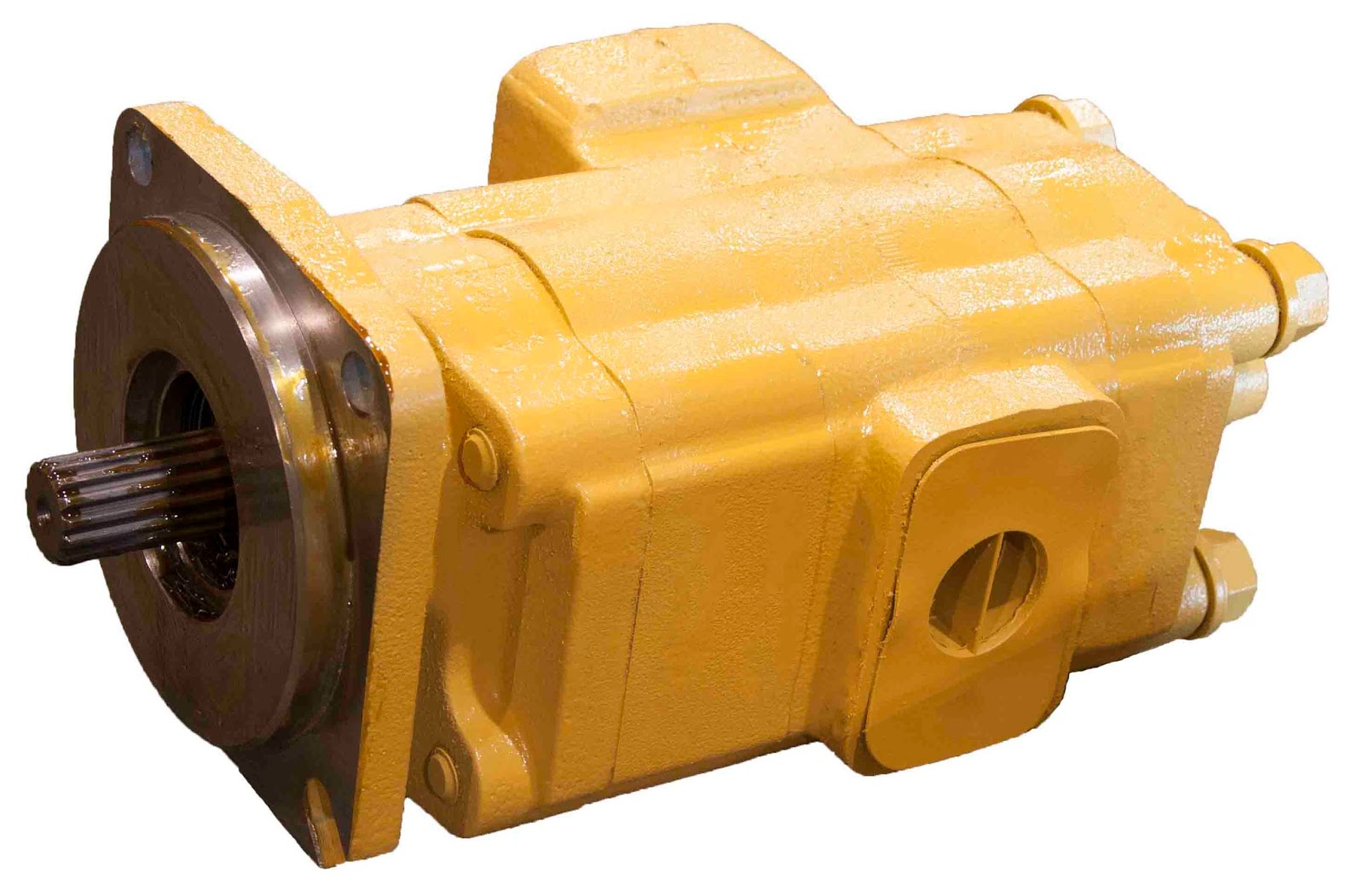

Click right here to learn extra about each kind. Now that you simply perceive the perform of each part, let’s look at how hydraulic pumps and motors work collectively. First, the hydraulic pump takes the mechanical power it receives from the prime mover and converts it into fluid power. This fluid energy takes the form of oil stream. After this, the hydraulic motor takes the fluid power that the pump created, and turns that fluid power into mechanical vitality. Pound for pound, these tanks require considerably less energy to supply than a comparable product made with steel. Complete hydraulic reservoir answer. The TNK’s design already enhances degassing, and paired with filtration powered by Air Fusion Know-how, air filtration is drastically augmented and system effectivity could be elevated. In comparison with a standard filter, the AFT reduces air in the suction line by 20% on the first cross. Superior air filtration increases the reliability and effectivity of your gear, saving you costly downtime.

You probably have considered the entire above questions, it is a good suggestion to evaluation the OEM's (authentic equipment producer's) specs. There could also be a guaranty-related cause to comply with the gear manufacturer’s recommendations. Nonetheless, in some applications, particularly these with extremes of temperature or other unusual working circumstances, using something totally different than what the manufacturer recommends may increase hydraulic system efficiency and reliability. In the event you wouldn't have the proper training to make such a decision, it is a good suggestion to speak with a technical specialist, preferably one that's vendor-neutral, as a result of this can really give you the best advice on your wants. How Have you learnt if You're Using the fitting Hydraulic Oil? 1. Mannesmann Rexroth. "Mineral Oil-based mostly Stress Fluids for Vane Pumps, Radial Piston Pumps and Gear Pumps as well as GM, GMRP, MCS, MCR, MR and MKM/MRM Motors." (RE 07 075/07.98), p.2. Brendan Casey has greater than 20 years expertise in the upkeep, restore and overhaul of mobile and industrial tools.

This conversion permits for the transfer of energy from one medium to another, which is essential in many industrial and commercial purposes. With out hydraulic pumps, many machines would not have the ability to function. Hydraulic pumps are of two primary sorts: optimistic displacement pumps and centrifugal pumps. Positive displacement pumps work by trapping a hard and fast fluid volume after which shifting it by means of the pump chamber. Caterpillar has developed synergies among products where technology and parts and ideas are used on the excavators. Some are pilot programs and others are electro-hydraulic that improve hydraulic efficiencies. Their advances in effectivity have been achieved with no trade-offs in performance versus the prior mannequin. Caterpillar has adopted "customer panels" that help to define the value they perceive to make their firms extra worthwhile, and what important necessities are wanted to help them to advance in the future and provide a greater return. Depreciation is another matter that always impacts hydraulic restore decisions. That’s because it begins as soon as a brand new part is put in. Plus, replacing an outdated component with a brand new one means including its depreciation on the company’s tax data. Consider the age of the defective hydraulic half earlier than shifting ahead with plans to change it. If it is already previous, it could make extra sense to rebuild or remanufacture it as a result of depreciation plateaus after a certain interval.